Do you know the performance of your data cabling for fire resistance? Most people don’t, and it’s not something that is really at the forefront of most people’s minds when it comes to slinging in a bit of CAT6. But… it’s actually quite important, and here’s why:

The CPR

No, not the “Stayin’ Alive” one. This is the Construction Products Regulation, an EU directive which states that any permanent cable installations must have a “Declaration of Performance” showing critical information such as Manufacturer, Product Type and the product Class.

Since 2017 this has been a legal requirement for all cabling placed into the EU market. It all sounds quite complicated, but realistically it just means that the manufacturer has to make this DoP information available to anyone using the product for up to ten years.

As a premium data cabling company we ensure that all of our cables are supplied by manufacturers and distributors that fully adhere to this directive.

The Classes

Cables provide a natural conduit for the spread of fire, particularly where they run through walls and between floors. In addition the materials used are often oil derived and as such are flammable in their unmodified form. Higher grade cables provide higher fire safety ratings, but also command higher prices. This is due to the materials used in the manufacturing process.

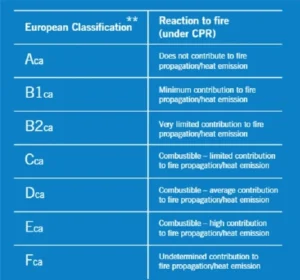

As you can see in figure 1.1, the ratings go from Aca (which is the best, but realistically unachievable for data cabling) to Fca (the worst). There are no regulations around which ratings should be used in which applications, this is left to the designer, architect or installer. It’s widely recognised that Fca should never be used in a commercial environment and BS6701 states that a minimum Cca.s1b.d2.a2 is used on all new construction, refurbishment or extension projects.

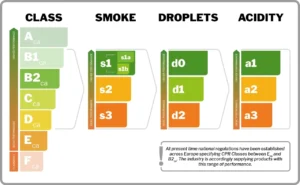

The s, d and a values refer to smoke, droplet and acidity performance. If the cable were to catch fire, these are the characteristics of the cable insulation. This is explained in figure 1.2.

LSOH vs PVC

LSOH (Low Smoke Zero Halogen, sometimes referred to as LSZH) is the gold standard in fire safe cable. PVC is combustible and produces thick black smoke, poisonous gasses and corrosive droplets. LSOH cable should be the cable you install in any building project purely on safety grounds.

The problem with PVC is the gasses it produces even before it begins to burn. PVC (Polyvinyl Chloride) gives off Hydrogen Chloride gas when heated or burned, which is highly toxic, and when mixed with moisture creates a corrosive Hydrochloric Acid.

Almost all of the permanent cabling we install is LSOH, unless explicitly specified by the customer for a particular application where the risks of using PVC have been identified.

Why Litenet?

We have extensive experience in providing structured cabling. We only supply and install compliant products and we take fire safety regulations very seriously. Our cables are sourced from premium manufacturers so that our customers can trust our work and be safe in the knowledge that they are complying with the regulations regarding their building project.

Need some cabling? Whether it’s copper CAT5E or 24 core OM4 Fibre we can supply and install it. Not sure what you need? Drop us a line and we can help, email info@litenetuk.com or call 01908 794 794